Define flow of fluids and Types of manometers Detailed Explanation with engaging Example

Flow of Fluids

The flow of fluids refers to the movement of liquids or gases under the influence of external forces such as pressure, gravity, or mechanical work. Understanding fluid flow is essential in pharmaceutical engineering, as it is applied in processes like filtration, mixing, and transportation of liquids in manufacturing units.

Fluid flow can be classified into two types:

- Laminar Flow: Smooth, orderly movement of fluid in layers (streamlines) with minimal mixing.

- Turbulent Flow: Chaotic, irregular movement with eddies and vortices, leading to significant mixing.

Fluid flow follows important principles like Bernoulli’s equation (pressure-flow relation), Poiseuille’s law (flow through narrow pipes), and Reynolds number (laminar vs. turbulent flow). These principles help in predicting fluid behavior in different conditions.

Manometers

A manometer is a device used to measure fluid pressure. It works on the principle of balancing a column of liquid (e.g., mercury or water) against the pressure being measured. Manometers are widely used in pharmaceutical industries to monitor pressure in pipelines, reactors, and filtration systems.

Types of Manometers

Below is a flow chart and table explaining the types of manometers:

Flow Chart:

Types of Manometers

(For very low pressure measurements)

Table:

| Type of Manometer | Description | Application |

|---|---|---|

| Piezometer Tube | A simple tube inserted into a fluid to measure pressure at a specific point. | Measures low pressures in open containers or tanks. |

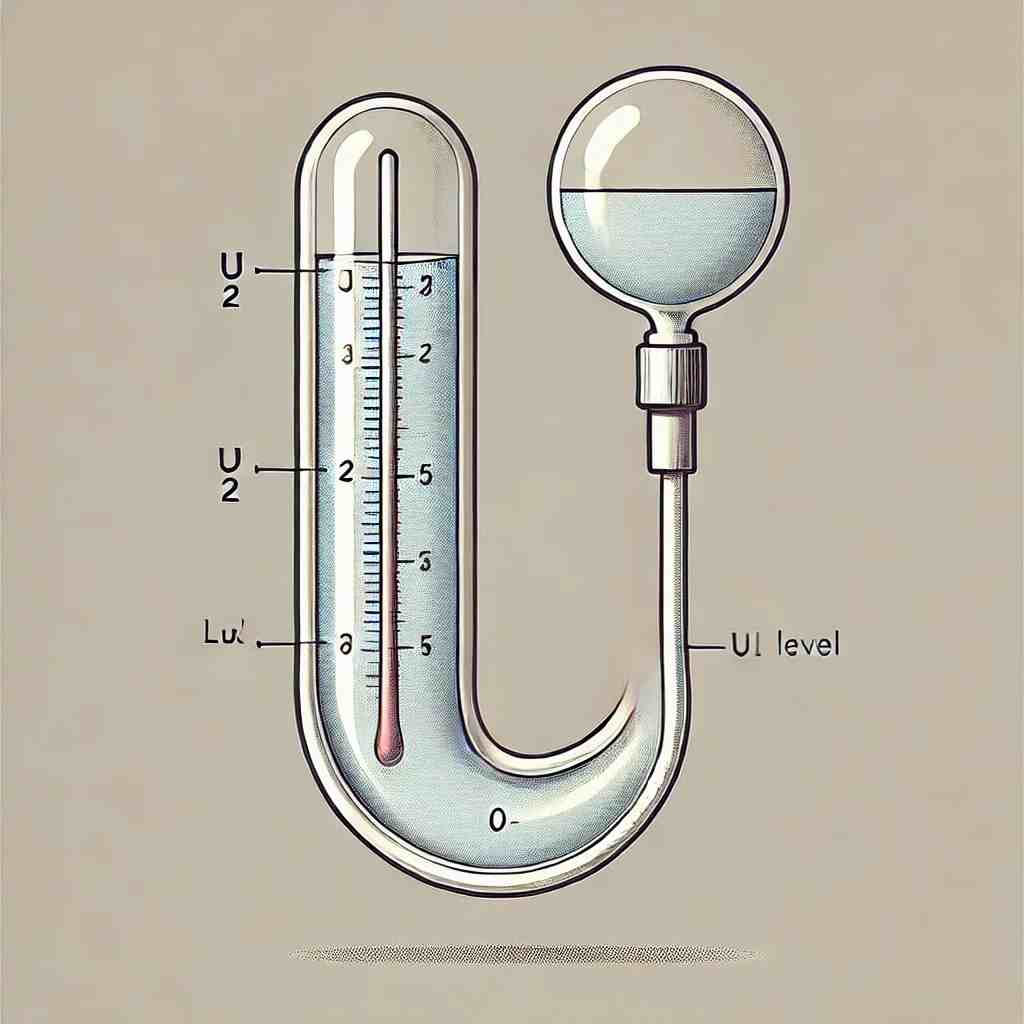

| U-Tube Manometer | A U-shaped tube filled with a liquid (e.g., mercury) to measure pressure. | Measures pressure in pipelines or closed systems. |

| Differential Manometer | Measures the difference in pressure between two points in a system. | Used in filtration systems or reactors to monitor pressure differences. |

| Inclined Manometer | A U-tube manometer with one limb inclined to amplify small pressure changes. | Measures very low pressures with high accuracy. |

| Micro Manometer | A highly sensitive manometer for measuring extremely low pressures. | Used in research labs or precision-based pharmaceutical processes. |

Detailed Explanation with Examples

- Piezometer Tube:

- Working: A simple tube inserted into a fluid. The height of the fluid column in the tube indicates the pressure.

- Example: Used to measure the pressure of a liquid in a storage tank.

- Working: A U-shaped tube filled with a denser liquid (e.g., mercury). The difference in liquid levels in the two limbs indicates the pressure.

- Example: A U-Tube manometer is used in pharmaceutical air filtration systems to measure the pressure difference, ensuring cleanroom compliance.

- U-Tube Manometer:

- Differential Manometer:

- Working: Measures the difference in pressure between two points by comparing the heights of liquid columns in a U-tube.

- Example: Used in filtration systems to monitor the pressure drop across a filter.

- Inclined Manometer:

- Working: One limb of the U-tube is inclined to magnify small pressure changes, making it easier to read.

- Example: Used in HVAC systems or low-pressure pharmaceutical processes.

- Micro Manometer:

- Working: A highly sensitive device that measures very low pressures using precision instruments.

- Example: Used in research labs to study fluid dynamics in microfluidic devices.

Practical Industry Example

Imagine you are working in a pharmaceutical manufacturing unit where a liquid drug is being filtered before packaging. The filtration system uses a differential manometer to monitor the pressure difference across the filter. If the pressure difference increases, it indicates that the filter is clogged and needs replacement. This ensures the efficiency of the filtration process and maintains the quality of the drug.

Key Takeaways

- Fluid flow is essential in pharmaceutical processes like filtration, mixing, and transportation.

- Manometers are critical tools for measuring pressure in various systems.

- Understanding the types of manometers and their applications helps in optimizing pharmaceutical manufacturing processes.

Why are fluid flow and pressure measurement crucial in pharmaceutical manufacturing? Share your opinion in the comments.